Is the trivial problem in bearing assembly cause huge trouble? The first Part

As far as Boyang concern,many belive that the installation method of the bearing varies with the bearing structure and matching conditions. Generally speaking, because most of the shaft rotates, the inner ring needs an interference fit. Bearings with cylindrical bores are usually pressed in with a press or hot-fitting method. In the case of a tapered hole, install it directly on the tapered shaft or use a sleeve.

However, when it is installed on the shell, there is generally a large amount of clearance fit and interference in the outer ring, which is usually pressed in with a press, or there is also a shrink fit method for installation after cooling. When dry ice is used as the coolant, the moisture in the air will condense on the surface of the bearing when the shrink fit is installed. Therefore, appropriate anti-rust measures are required. The installation of bearings generally requires professional tools such as bearing heaters.

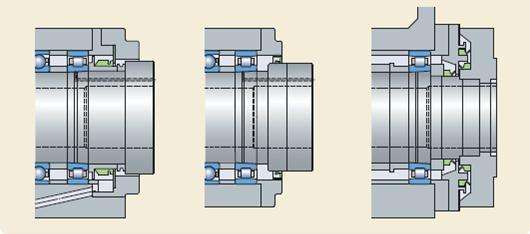

1. Installation of tapered bore bearings

The tapered bore bearing is to directly fix the inner ring on the tapered shaft, or install it on the cylindrical shaft with an adapter sleeve or a disassembly sleeve. Large-scale self-aligning bearings are mostly installed by oil pressure.

2. Operation inspection

After the bearing is installed, in order to check whether the installation is correct, it is necessary to perform a running check. The small machine can be rotated by hand to confirm whether the rotation is smooth. The inspection items include poor operation due to foreign objects, scars, indentation, uneven rotation torque due to poor installation, poor mounting seat processing, large torque caused by too small clearance, installation error, seal friction, etc. . If there is no abnormality, power operation can be started.

Because large machinery cannot be rotated manually, immediately turn off the power after starting without load, perform inertial operation, check for vibration, sound, and contact with rotating parts, etc., and enter power operation after confirming that there is no abnormality.

Power operation starts at low speed with no load and slowly increases to the rated operation under the specified conditions. The items to be checked during the test run are whether there are abnormal noises, bearing temperature shifts, lubricant leakage and discoloration, etc. If abnormality is found during trial operation, the operation should be stopped immediately, the machine should be inspected, and the bearing should be removed for inspection if necessary.

Bearing temperature inspection is generally inferred from the appearance of the housing. However, it is more accurate to directly measure the temperature of the outer ring of the bearing by using the oil hole. The bearing temperature starts to rise gradually, if there is no abnormality, it usually stabilizes after 1 to 2 hours. If the bearing or installation is defective, the bearing temperature will rise sharply, resulting in abnormally high temperature. The reasons include too much lubricant, too small bearing clearance, poor installation, and excessive friction of the sealing device. In the case of high-speed rotation, the wrong choice of bearing lubrication method is also the cause.

English

English Spanish

Spanish French

French German

German Czech

Czech Portugal

Portugal Italy

Italy Korean

Korean Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish Arabic

Arabic Russian

Russian Czech

Czech Thai

Thai Irish

Irish Bulgarian

Bulgarian Poland

Poland Croatian

Croatian Ukrainian

Ukrainian Bosnian

Bosnian Lithuanian

Lithuanian Latvian

Latvian Romanian

Romanian Greek

Greek Danish

Danish Hungary

Hungary Norwegian

Norwegian Finnish

Finnish Dutch

Dutch Swedish

Swedish Slovak

Slovak Slovenian

Slovenian Indonesian

Indonesian Bengali

Bengali Serbian

Serbian Uzbek

Uzbek