Is the trivial problem in bearing assembly cause huge trouble? The second Part

The installation of Cylindrical Bore Bearing

1) Method of pressing in with a press machine

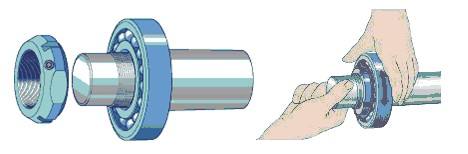

Small bearings are widely use a press machine. Pad the spacer block into the inner ring, and press it statically with a press machine until the inner ring is in close contact with the shaft shoulder. Mounting the outer ring with a spacer block to install the inner ring is the cause of indentation and crushing on the raceway, so it is absolutely prohibited.

During operation, it is better to apply oil to the mating surface in advance. As a last resort, use a hammer to hit the installation, and do put a block on the inner ring. This practice has become the a common bearing operation, but it is limited to the case of small interference, and cannot be used for large interference, or medium and large bearings.

For non-separable bearings of deep groove ball bearings, where the inner ring and outer ring need to be installed with interference, use a cushion block to pad, use screw or oil pressure to press in the inner ring and outer ring at the same time. The outer ring of self-aligning ball bearing is easy to tilt, even if it is not an interference fit, it is best to install it with a spacer.

For separable bearings such as cylindrical roller bearings and tapered roller bearings, the inner ring and outer ring can be installed on the shaft and housing respectively. When combining the installed inner ring and outer ring, the key is stability Close the two firmly so that the center of the two does not deviate, and pressing in will cause the raceway surface to jam.

2) Hot loading method

For large bearings installation, it is difficult to press in because it requires a lot of force. Therefore, the hot fitting method of heating the bearing in oil to expand it and then installing it on the shaft is widely used. Using this method, the operation can be completed in a short time without adding improper force to the bearing.

The heating temperature of the bearing is based on the bearing size and the required interference.

The precautions as follows:

(a) Do not heat the bearing above 120℃;

(b) In order to prevent the bearing from directly touching the bottom of the oil tank, it is best to consider placing the bearing on a metal mesh table or hoisting the bearing;

(c) Heat the bearing to 20°C-30°C higher than the required temperature, so that the inner ring does not become cold during operation and it is difficult to install;

(d) After installation, the bearing cools down and shrinks in the width direction, so use a shaft nut or other appropriate method to tighten it to prevent a gap between the inner ring and the bearing shoulder.

BoYang Bearing will updates a further chapter soon.

Kindly go back to HOME if you are interest in Stainless steel Bearing.

English

English Spanish

Spanish French

French German

German Czech

Czech Portugal

Portugal Italy

Italy Korean

Korean Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish Arabic

Arabic Russian

Russian Czech

Czech Thai

Thai Irish

Irish Bulgarian

Bulgarian Poland

Poland Croatian

Croatian Ukrainian

Ukrainian Bosnian

Bosnian Lithuanian

Lithuanian Latvian

Latvian Romanian

Romanian Greek

Greek Danish

Danish Hungary

Hungary Norwegian

Norwegian Finnish

Finnish Dutch

Dutch Swedish

Swedish Slovak

Slovak Slovenian

Slovenian Indonesian

Indonesian Bengali

Bengali Serbian

Serbian Uzbek

Uzbek